Back in May 2015, Indian food safety authorities

outlawed the production and sale of an instant noodle product, manufactured by

a leading global brand, for high level of MSG.

As the ban surfaced, the company struggled to recall affected instant noodle packs from its supply chain spread across the country. The company was unable to access as much as 35–40% of the total stock as thousands of outlets selling the product are outside the company’s direct reach or network. Recalling a faulty product proved difficult, especially from the rural areas.

As a result, the only retort available to the company was to destroy the whole stock, wherever found in the supply chain. Trucks of material were destroyed, leading to huge losses in cost and reputation.

Brand owners need to be always prepared for the uncalled situations like the above. The sheer preparedness will not only save huge costs by exactly targeting the stock that needs to be recalled but also save the brand image, portraying it as responsible organisation working towards consumer safety.

The preparedness in this case is an effective recall mechanism with proper guidelines and strategies. Let’s understand what it entails.

Either mandated by the Regulator or voluntarily initiated by the brand owner, product recall is a process of recovering products/consignments batch-wise from your supply chains, spanning the whole market. An effective recall system is based on visibility to the whole of the supply chain and needs seamless data flow among supply chain partners with unambiguous and unique identification of products, consignments, locations, parties, and documents.

Standards-based solution to recalls

The objective of a product recall system is to encourage speedy, transparent, localized product withdrawals from the whole of supply chain whenever required. This requires implementation of global supply chain standards — GTS (Global Traceability Standard).

The Global Traceability Standard functions as a blueprint for all supply chain partners that enables them to share product/consignment information at each checkpoint in a manner that enables complete supply chain visibility.

The GS1 GTS is intended for use across end-to-end supply chains and is relevant to all events that span the lifecycle of a traceable object, including:

As the ban surfaced, the company struggled to recall affected instant noodle packs from its supply chain spread across the country. The company was unable to access as much as 35–40% of the total stock as thousands of outlets selling the product are outside the company’s direct reach or network. Recalling a faulty product proved difficult, especially from the rural areas.

As a result, the only retort available to the company was to destroy the whole stock, wherever found in the supply chain. Trucks of material were destroyed, leading to huge losses in cost and reputation.

Brand owners need to be always prepared for the uncalled situations like the above. The sheer preparedness will not only save huge costs by exactly targeting the stock that needs to be recalled but also save the brand image, portraying it as responsible organisation working towards consumer safety.

The preparedness in this case is an effective recall mechanism with proper guidelines and strategies. Let’s understand what it entails.

Either mandated by the Regulator or voluntarily initiated by the brand owner, product recall is a process of recovering products/consignments batch-wise from your supply chains, spanning the whole market. An effective recall system is based on visibility to the whole of the supply chain and needs seamless data flow among supply chain partners with unambiguous and unique identification of products, consignments, locations, parties, and documents.

Standards-based solution to recalls

The objective of a product recall system is to encourage speedy, transparent, localized product withdrawals from the whole of supply chain whenever required. This requires implementation of global supply chain standards — GTS (Global Traceability Standard).

The Global Traceability Standard functions as a blueprint for all supply chain partners that enables them to share product/consignment information at each checkpoint in a manner that enables complete supply chain visibility.

The GS1 GTS is intended for use across end-to-end supply chains and is relevant to all events that span the lifecycle of a traceable object, including:

- The transformation and processing of raw materials,

ingredients, intermediate products, components and components into the

product.

- Aggregation and disaggregation of products and linkage

to assets (e.g., returnable assets).

- Transport and distribution, including cross-border

trade.

- The maintenance, repair and overhaul operations across

multiple cycles of usage or service of the product.

- Consumption of products, including dispensing and

administering.

- The disposal and destruction of the product and the

recycling of materials.

It also provides a foundation to enable data

sharing across more complex supply chains, where parties need to find and retrieve

information from companies that are not their direct trading partners and where

trust may need to be established before data can be shared.

The need for unique identification

At the heart of a traceability system is the identification of traceable objects, which is encoded in the form of barcodes. A traceable object is a physical or digital object for which there is a need to retrieve information about its history, application, or location. Examples of traceable objects include products (e.g., consumer goods, medicines, electronic devices), logistic units (e.g., palletised goods, parcels) and assets (e.g., trucks, vessels, trains, forklifts).

For the physical identification of traceable objects, generally three main levels of identification can be distinguished:

The need for unique identification

At the heart of a traceability system is the identification of traceable objects, which is encoded in the form of barcodes. A traceable object is a physical or digital object for which there is a need to retrieve information about its history, application, or location. Examples of traceable objects include products (e.g., consumer goods, medicines, electronic devices), logistic units (e.g., palletised goods, parcels) and assets (e.g., trucks, vessels, trains, forklifts).

For the physical identification of traceable objects, generally three main levels of identification can be distinguished:

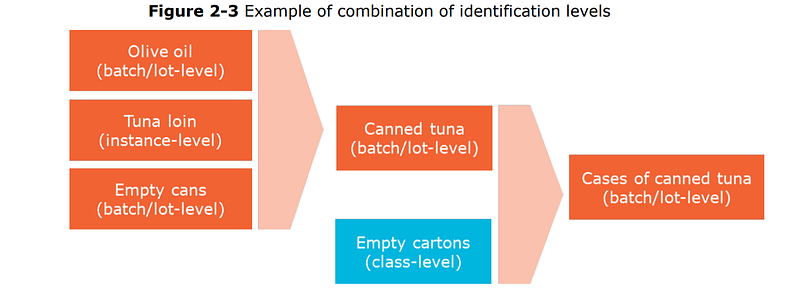

- Class-level identification, where the object is

identifiable by its product / part ID, enabling it to be distinguished

from different kinds of products or parts.

- Batch/lot-level identification, where the product /

part ID is extended with a batch/lot number, limiting the number of

traceable objects with the same ID to a smaller group of instances (for

example, items produced at the same time).

- Instance-level identification, where the traceable

object is identified with a serialised ID, limiting the number of

traceable objects with the same ID to one individual instance.

The objectives of the traceability system and the supply chain itself are key criteria to determine the right level of identification. Companies will often apply a combination of identification levels.

Once, this unique identification system is in place, along with the digital infrastructure required by GTS, using which each supply chain stakeholder has transparency, recalls becomes efficient and effective.

Comments

Post a Comment